Any experienced ISO Quality Manager will tell you - the secret to planning a successful ISO implementation is to break the process down into manageable steps and gain the support of top-management for your project plan.

Our ISO 9001 Project Plan Template is proven to work.

When it comes to making such a big change in your organization, knowledge is power. ISO 9001 can be difficult to grasp. The requirements it lays out are numerous but they are all there for a reason. Before taking any steps toward certification it's crucial that you know exactly what's being asked of you.

You should decide first and foremost what sort of approach you want to take to certification. This will help you on your journey to certification. There are a few ways you can go about implementing ISO 9001 in your business:

The most popular approach by far is to implement ISO 9001 in-house. Whether or not a company chooses to purchase an ISO Template or certification kit is up to them. These kits are relatively inexpensive, and a great time saver if you do not have to have any type of prior experience, however, if you may feel you have a good enough grasp on the materials to be able to do it all yourself. By all means, go for it!

A big part of familiarizing yourself with ISO 9001 is understanding the requirements that you must meet and how they relate to your company. These requirements are broken down into sections in the standard. With these sections, you can easily separate the processes within your organization into what section of requirements they apply to.

Sections 4-10 are the ones you should look to in order to find the requirements of the standard.

You should decide on one person in your organization that will be the lead during the entire certification process. This person is generally a quality manager or a leader that is already incredibly familiar with the way your organization functions. Your leader will be known as your Management Representative.

The Management Representative will be responsible for the entire implementation of ISO 9001 in your business. They should have appropriate authority to make changes to operations and have a strong grasp on ISO 9001 and how it works for your business.

If your company has more than one physical location, a Management Representative should be appointed at each one. One main Management Representative from corporate would oversee the progress of all of the local Management Representatives to ensure they are doing their jobs.

As well as the top person, every member of your Top Management team should be 100% on-board with the change about to happen. You should have the support and understanding of every member of leadership. This is crucial for a smooth transition.

The foundation of your move to an ISO 9001 compliant system is supported by your Top Management. Training will be required to ensure they know exactly what it is will be happening.

After Top Management is ready to move forward, you should involve and inform the rest of your employees. ISO 9001 implementation will affect every level of your business and the processes that go into making it work. It's best to let everyone who works on these processes know early on what they are in for and gain their support.

The support from all employees is crucial to the success of ISO 9001. If they feel threatened by a change they didn't know was coming they may become more of a hindrance than a help. You should have meetings and seminars with groups of employees from the different sectors of your business and present all the needed information in a way they can understand.

Construct an ISO 9001 Project Plan. Top Management buy-in is essential to not only planning Management Reviews, but ensuring that the whole process goes more smoothly.

A plan is best created when you have a team in place that is capable of reaching your objectives. Your team should be comprised of managers from the different areas of your company that have the authority to implement change in their area. They will all be under your Management Representative.

Having a team in place will make achieving certification that much easier. They will each have set out responsibilities and be able to keep everyone in their area on task. The team will meet regularly during implementation to monitor progress, allocate resources, answer questions, and coordinate all facets of the new quality management system.

Once you know how you're already doing, it's time to sit down and make a plan for the future. You should create a time-line for implementation with set dates and deadlines to get things done. With a time-line set into place, you can more easily stay on task without other things drawing your focus.

Our ISO 9001 Project Plan Template is proven to work.

A gap analysis is a good way to see how the system you already have in place compares to the ISO 9001 standard. By doing this you will be able to make lists of what is already in place and what needs to be put into place in order to meet the requirements. You may be able to make to-do lists for each section of the standard.

There are many gap analysis checklists available online (learn about our Gap Analysis tools) that may be helpful to your company when it comes to finding out how you stack up against ISO 9001 in your current state. You could also hire an auditor and let them know that you wish to see what parts of your system are already meeting the requirements.

Developing your documentation can be a tedious task, one that many people won't be looking forward to. There are many technical requirements for documentation within the ISO 9001 standard that will probably mean you have a lot of reworking to do.

It is essential that your documentation is developed in accordance with the ISO 9001 requirements, and not just for the purposes of seeking certification. With properly written and available instructions and procedures it becomes much easier to introduce new processes into the fold. Everyone can benefit from proper documentation.

Because it is at the beginning of the process, getting all of your documentation ready can seemingly slow down the process to a screeching halt. There are ways to speed it up. You can purchase ready-made templates that make inputting the information quick and easy. Or you can create templates of your own that suit your company's needs.

Our Quality Manual Template is proven to work.

All of your documentation should be specific to your organization and entirely relevant. It should also be written in a clear way that is easy to navigate and understand. Documents should be easy for everyone within the company to gain access to should they need them.

You will be required to have a control system in place for your documentation that shows records of approval, updates, and revisions of documents. Only the most current version of any document should be available for your employees to access, giving them only the information they need.

It is now time to start putting your new system into action. You will start to follow the carefully laid plans you made in order to transition to the quality management system you need. It's important to take this part one step at a time.

Implementing a new system will likely affect every single employee within your organization and the way they conduct your work. Include the employees in developing work instructions whenever possible. That way, if they are changed in some way to meet the requirements, they will be in on it from the beginning. They are more likely to understand what is being asked of them if they have a hand in developing it.

During the implementation process, you will need to conduct a number of management reviews. These reviews will take the output of what changes you made and where improvements can be made. Use all the information you have on hand from every process that contributes to your quality management system. Always find ways to make it better.

During implementation and even after certification you will need to perform internal audits to ensure your quality management system is meeting requirements. These audits are performed by one or more members of your own staff who have been trained to do so.

Training an employee to do an internal audit can be done with easy online courses that give them all the tools they need to do their job. At smaller companies, it may be the Management Representative that audits the entire company other than the work they are directly responsible for. If someone audits their own work, it is considered a nonconformity.

You don't have to audit the entire company all at once. It's possible to only audit a single area or process within your company at a time. You should begin internal audits during the implementation process so that you can see where things might not be quite working. The results of these audits can be used at management reviews to make improvements.

Once you are ready to go, it will be time for someone independent of your company to come in and audit it. This person will be your registrar and will carry you through to certification. Make sure to pick a registrar that is accredited by a national certification body. Whatever auditor you work with should be fully qualified to audit your specific organization.

Help choosing your ISO consultant

Once you choose a registrar they will send an auditor to your organization to evaluate how well you are meeting the requirements. They will audit both your documentation and your processes. Unless they uncover significant problems with your quality management system, you are likely to receive your ISO 9001 certification.

Before the audit, it is essential to prepare your employees for what is coming. Make sure they all know when the audit will take place and the purpose of it. It would be helpful to practice answering questions that the auditor may ask. They should answer clearly and show they have a good understanding of their part in the system.

Check to be sure your facility is ready for the audit. Clean everything up and get rid of any mess that may be lying around. Put all documents in place and make sure none are lying around where they're not meant to be. Check that notice boards are all up to date information.

Have somewhere for the auditor to work, a quiet office of some kind. They will have to spend a good amount of time checking over your documentation and won't be out in the facility the entire time. Make sure you have your quality policy and procedures readily available.

There should be one employee assigned to take the auditor through the facility to show them where the different areas are located. They should be trained not to answer any questions unless directed specifically to them. The other employees should be the ones to answer.

If you have no major nonconformities present in your quality management system, you will be granted your ISO 9001 certification. The process doesn't end there, though. One of the requirements of ISO 9001 is to continue to improve, something the certification body will keep track of.

You shouldn't lose focus on your certification and the maintenance of your quality management system after you receive it. An auditor will be sent to perform a surveillance audit once or twice a year to ensure your organization continues to comply with the standard as well as constantly improve.

Constant monitoring and review of your quality management system is a must. You should have objectives in place that make results easy to measure and interpret by all members of your team. These reviews should review where changes need to be made as well as areas for opportunity.

Internal audits and management reviews are an excellent way to keep track of the performance of your quality management system. Both of these procedures should be planned at regular intervals to ensure nothing is falling behind the requirements. It is also easier to find risks and opportunities when you have this sort of information.

With the addition of customer and employee feedback, it will be easy for your organization to constantly be improving your system. You can implement a Plan-Do-Check-Act sort of system to guide your improvement efforts. These four steps give you a simple framework to work toward successful change.

With the help of these steps, your organization can create an efficient quality management system that is perfectly suited to the ISO 9001 standard. Once you have everything set into place, it will be easy to continue to meet the requirements. Good monitoring and review practices ensure your system remains up to the standard far into the future.

Remember not to look at the certification process as a whole. It's impossible to start out if you are worried already about your final audit. Take it one step at a time and set yourself up for success from the beginning. Before you know it you will have your ISO 9001 certification in hand.

Getting Started with ISO 9001

Updated: 17st April 2024

Author: Richard Keen

Richard is our Compliance Director, responsible for content & product development.

But most importantly he is ISO's biggest fanboy and a true evangelist of the standards.

Learn more about Richard

Don’t Try to Manage It All Alone!

Our ISO Auditors and Quality Manager Trainers have been in this industry for years, and since 2002 we’ve been providing thousands of small businesses and large corporations with the tools they need to get certified.

Instead of trying to create a project plan and checklist from scratch, use ours.

Before you invest all the hours reinventing the wheel, before you spend countless dollars outsourcing the task — try our templates.

| QMS ISO 9001 |

EMS ISO 14001 |

OH&S ISO 45001 |

|||

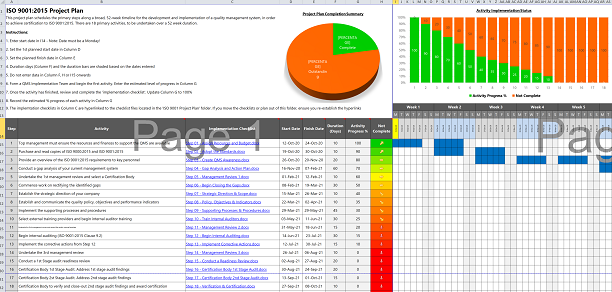

ISO 9001 Project Plan and Implementation Checklists |

A complete 18-step project plan for ISO 9001 using MS Excel.

Implementation checklists for each of the 18 steps, MS Word.

|

|

$39 USD |

||

ISO 14001 Project Plan and Implementation Checklists |

A complete 18-step project plan for ISO 14001 using MS Excel.

Implementation checklists for each of the 18 steps, MS Word.

|

|

|

$39 USD |

|

ISO 45001 Project Plan and Implementation Checklists |

A complete 18-step project plan for ISO 45001 using MS Excel.

Implementation checklists for each of the 18 steps, MS Word.

|

|

|

$39 USD |

|

ISO 9001 + ISO 14001 |

A complete 18-step project plan for ISO 9001 and ISO 14001.

Implementation checklists for each of the 18 steps, MS Word.

|

|

$39 USD |

||

ISO 9001 + ISO 45001 |

A complete 18-step project plan for ISO 9001 and ISO 45001 using MS Excel.

Implementation checklists for each of the 18 steps, MS Word.

|

|

$39 USD |

$39 USD |

|

ISO 9001 + ISO 14001 + |ISO 45001 |

An integrated 18-step project plan for

Implementation checklists for each of the 18 steps, MS Word.

|

|

$39 USD |

||

Pay by Credit Card, Debit Card, PayPal or Apple Pay.

|

Please read our Money Back Guarantee. |

Bought by Small Businesses and Large Corporations our templates have been sold online and CD since 2002.

Used by:

The Templates are used by first-timers following our step-by-step, clause-by-clause guidance documents; and experienced Quality Managers wishing to streamline and improve their existing documentation.

The application of our templates is scalable and generic; regardless of the size and type of organization. The elements that form the quality management system are the same.

1. Our customizable templates save you time and money by offering a streamlined process to create your quality documentation

2. They’ve got everything you need in one simple template

3. Proven to work our templates have helped thousands of businesses big and small achieve certification

4. Documents use styles to make reformatting and rebranding a breeze

5. Our templates are generalizable for any industry or sector. The application of our templates is scalable and generic; regardless of the size and type of organization.