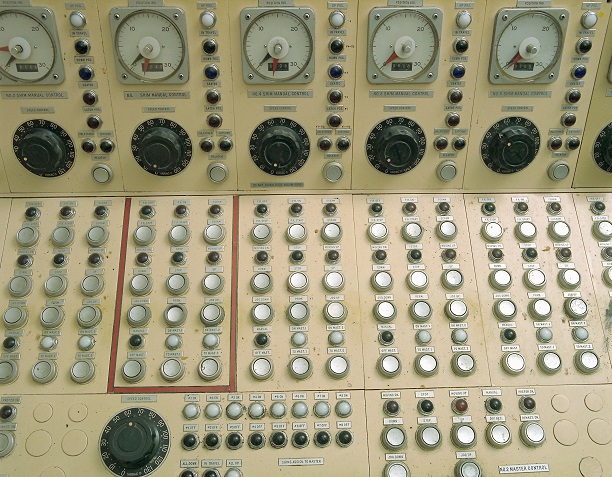

The calibrated equipment process is considered a crucial procedure in quality management. It ensures that all measurement and test instruments used in the design, manufacture, and testing of components, in-process sub components and finished products or devices are accurate and effective.

Contents

In order to verify product and process conformity, it is often necessary to have inspection and test equipment that is calibrated. This means that all the measuring equipment needs to be tested regularly for accuracy and the tolerances checked against any applicable reference standards or measures to ensure the measurements taken are accurate.

Read on for more insights into this process, how to execute it, and its benefits.

A calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration.

It is a legal requirement that organizations meet the calibration schcedule for all measuring equipment. This is to ensure that the integrity of the organization’s work is within an allowable tolerance range at all times.

Our Calibrated Equipment Procedure is proven to work.

The calibrated equipment procedure includes details such as the frequency of calibrations and the people responsible for carrying them out. It also provides any other information or conditions regarding calibration that may have been agreed upon when purchasing equipment.

When writing the procedure, it’s crucial to ensure that any relevant standards, such as the ISO 9001, are mentioned so that employees don’t doubt the accuracy of tests and measurements.

The quality assurance department is responsible for designing, implementing, and maintaining the calibrated equipment procedure. They are also responsible for calibration administration responsibilities as defined by this document.

In the calibration procedure, the Quality Manager department needs to detail who will be responsible for carrying out each calibration stage.

As an organization, you should ensure that each section has a person in charge who is directly accountable for any defective equipment or inaccurate data being used by the organization.

It is also good practice to identify a calibration supervisor responsible for ensuring that all required measurements are taken, and equipment is regularly calibrated.

To establish a calibrated equipment procedure, please follow these steps:

The most important part of calibration is to know what you are calibrating. As a rule of thumb, it’s best if you make a list with the name and description of any equipment used by your organization.

It is crucial to prioritize the pieces to be tested based on how frequently workers at your company employ them. Once this is determined, it becomes easier to identify who needs training for specific devices so errors don’t happen when using them.

Once you have identified what needs to be calibrated, you can then decide whether this will need to be done as part of an existing process or if there is a separate procedure in place for it.

For example, if you need to calibrate a pH meter, this could be carried out as part of routine maintenance.

You may need to establish a separate procedure if you need to test a different piece of equipment. Each measurement instrument should be traceable through its own calibration record, which contains:

For software testing, calibration might include the input of normal and abnormal (limited case) data to test programming performance and error handling to assure the software and associated equipment meet the specifications.

The test protocol, testing, results, and reviews should be documented, and any changes to the programming should be formally reviewed and approved before final acceptance.

Similarly, validated, automated machine tools such as lathes, printed-circuit drills, and component inserters can be monitored and maintained by conducting a ‘first’ and ‘last-piece’ inspection of representative product lots to assure accuracy.

You’ll need to decide which frequency calibration should occur, depending on the equipment and its usage. For example, equipment that operates in high-risk fields like food safety may need calibration more frequently than other machines.

The calibration frequency is usually determined by comparing the performance of the measuring equipment to:

The selection and training of competent calibration personnel is an important consideration and the personnel involved with calibration possess the following qualities:

Decide who will be responsible for carrying out each calibration process. It’s crucial to assign primary responsibility for specific areas within this procedure. Some of it may be carried out by separate departments. In general, the Quality Manager is required to:

All employees and Process Owners are required to:

For example, suppose you need a piece of equipment used across your organization calibrated. In that case, each department should be able to carry out the measurement.

A commercial laboratory accredited to ISO 17025 should be used for calibration when calibration cannot be accomplished in-house.

The team must decide how they will store calibration tools. They can choose to keep them in one designated place with a lock or two separate locations that are locked and secure at all times, such as the Quality Manager’s office or in close proximity to the technicians on duty.

As appropriate, ensure that environmental controls are established and maintained to ensure that monitoring and measuring instruments are calibrated, and used in conditions that will not adversely affect the accuracy of the measurements.

Consideration must be given to the effects of temperature, humidity, vibration, and cleanliness when purchasing, using, calibrating, and storing instruments.

This way, only authorized personnel can access these items when needed for calibrating equipment during operations hours.

Our Calibrated Equipment Procedure is proven to work.

Decide which standards and procedures will be used to ensure correct calibration. It may help if you check whether the standards require you to include anything specific in this procedure to meet their requirements. For example, ISO 9001 states that the Quality Manager should administer the calibration procedure.

There are many benefits to having a calibrated equipment procedure in place. One of the main advantages is that it shows everyone involved how to maintain accuracy throughout the stages of testing. This means that you will avoid problems with your product or documentation being inaccurate.

Another benefit is that it makes the calibration process easier to carry out. The calibration procedure should serve as a reminder of what needs to be done during each stage and when it’s due. This means that technicians won’t worry about missing deadlines or forgetting essential processes.

It also gives you an audit trail for any future changes, modifications, or additions to the equipment. The procedure should be kept up-to-date if there are any changes. Otherwise, you may run into problems in the event of an audit by the regulator.

All monitoring and measurement equipment and software performance data is reviewed by the Quality Manager. Audits of software and equipment maintenance procedures and records should evaluate the adequacy of safeguards, change controls, and other controls necessary to maintain software quality and proper performance of associated equipment.

The audits must be documented, important results are reviewed with management, and corrective action taken as appropriate.

Our Calibrated Equipment Procedure is proven to work.

Updated: 26th February 2022

Author: Richard Keen

Richard is our Compliance Director, responsible for content & product development.

But most importantly he is ISO's biggest fanboy and a true evangelist of the standards.

Learn more about Richard

Don’t Try to Manage It All Alone!

Our ISO Auditors and Quality Manager Trainers have been in this industry for years, and since 2002 we’ve been providing thousands of small businesses and large corporations with the tools they need to get certified.

Instead of trying to create everything you need to follow this process from scratch, use ours. We have procedures, templates, checklists, process maps, forms and gap analysis tools to help you control your documented information without missing a single input or output.

Before you invest all the hours reinventing the wheel, before you spend countless dollars outsourcing the task — try our templates.

| QMS ISO 9001 |

EMS ISO 14001 |

OH&S ISO 45001 |

|

|

Calibrated Equipment Procedure The purpose of this procedure is to ensure that all inspection and test equipment used for product, service and process verification is controlled and calibrated against nationally traceable standards at specified intervals and that such devices are available to ensure continuity of measurement capability. Forms & Reports also included:

>> Free Download - Control of Calibrated Equipment Procedure - this will give you a good idea of what to expect when you purchase the procedure. |

$19 USD |

|

Pay by Credit Card, Debit Card, PayPal or Apple Pay.

|

Please read our Money Back Guarantee. |

Bought by Small Businesses and Large Corporations our templates have been sold online and CD since 2002.

Used by:

The Templates are used by first-timers following our step-by-step, clause-by-clause guidance documents; and experienced Quality Managers wishing to streamline and improve their existing documentation.

The application of our templates and quality manuals is scalable and generic; regardless of the size and type of organization. The elements that form the quality management system are the same.

1. Our customizable templates save you time and money by offering a streamlined process to create your quality documentation

2. They’ve got everything you need in one simple template

3. Proven to work our templates have helped thousands of businesses big and small achieve certification

4. Documents use styles to make reformatting and rebranding a breeze

5. Our templates are generalizable for any industry or sector. The application of our templates is scalable and generic; regardless of the size and type of organization.