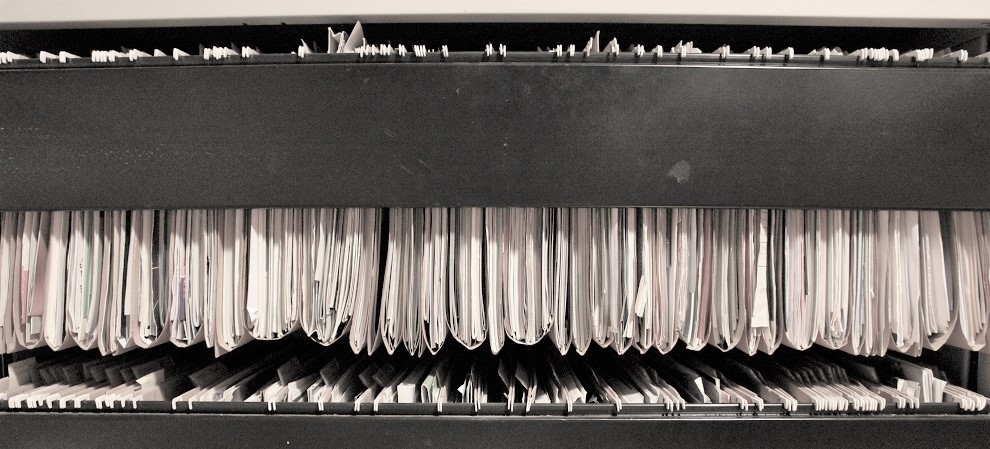

Worried about Document Control? Our advice is to keep your ISO 9001 quality management system as simple as possible.

The fewer records and documented information you keep, the fewer things that will be audited.

Register of Documented Information - Your organization must maintain the following as Documented Information:

| ISO 9001:2015 Clause | Description |

|---|---|

| 4.3 | The scope of the quality management system |

| 4.4 | Information necessary to support the operation of QMS processes |

| 5.2 | The quality policy |

| 6.2 | The quality objectives |

Register of Documented Information - Your organization must retain the following as Documented Information:

| ISO 9001:2015 Clause | Description |

|---|---|

| 4.4 | Information necessary to support the operation of QMS processes |

| 7.1.5.1 | Evidence of fitness for purpose of monitoring and measuring resources |

| 7.1.5.2 | Evidence of the basis used for calibration of the monitoring and measurement resources |

| 7.2 | Evidence of competence of people doing work under the control of the organization that affects the performance and effectiveness of the QMS |

| 7.5.1b | Documented information required by the QMS |

| 8.2.3 | Results of the review and requirements for the products and services |

| 8.3.2 | Records to demonstrate compliance with design and development requirements |

| 8.3.3 | Records of design and development inputs |

| 8.3.4 | Records of the activities of design and development controls |

| 8.3.5 | Records of design and development outputs |

| 8.3.6 | Design and development changes, including the results of the review and the authorization of the changes and necessary actions |

| 8.4.1 | Records of the evaluation, selection, monitoring of performance and re-evaluation of external providers and any actions arising |

| 8.5.2 | Evidence of the unique identification of outputs when traceability is a requirement |

| 8.5.3 | Records of property of the customer or external provider that is lost, damaged or non-conforming and of its communication to the owner |

| 8.5.6 | Results of the review of changes for production or service provision, the persons authorizing the change, and necessary actions taken |

| 8.6 | Records of authorized release of products for delivery to the customer including acceptance criteria and traceability to the authorizing person(s) |

| 8.7 | Records of non-conformities, actions taken, concessions and the identity of the authority deciding the action in respect of the nonconformity |

| 9.1.1 | Results of the evaluation of the performance and the effectiveness of the QMS |

| 9.2.2 | Evidence of the implementation of the audit programme and the audit results |

| 9.3.3 | Evidence of the results of management reviews |

| 10.2.2 | Evidence of the nature of the nonconformities and any subsequent actions taken |

| 10.2.2 | Results of any corrective actions |

>> What are the Documentation Information requirements?

>> Review the current ISO 9001 mandatory procedures

All of the ISO 9001 requirements are fully-documented and explained in our QMS Templates.